Watermaster 70, 5 Stage Pumped 75GPD Reverse Osmosis Drinking Water System

Replacement Cartridges

Every Six Months:

- D-FD310-1 (5 Micron)

- D-FD310-2 (1 Micron)

- D-FD310-3 (G.A.C.)

- D-10-2 (70 GPD Membrane)

- D-FTQ10-7 (Post Carbon)

| Components of the filter:

The model is supplied with domestic pump intended for water mains with low pressure. The pump will provide the pressure necessary for pushing water through the membrane. The model is assembled with the special metal supporting structure to provide fixation of the filter, as well as convenience and simplicity of its maintenance. Stages of water purification The feed water flows through the three pre-filters intended to reduce sediments (rust, sand, silt etc.), chlorine and chlorination by-products, as well as organic matter. The fourth stage is represented by the reverse osmosis membrane which at the molecular level purifies the water from 99.8% impurities including bacteria and viruses. The purified water is supplied to the storage tank. The carbon post-filter is the fifth stage of the water treatment. It contains high-quality activated coconut shell carbon which improves purified water taste and odor, and adds slight sophisticated sweetish flavor. Characteristics of the equipment

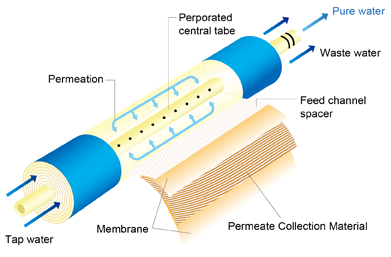

* If pressure in the water supply system is lower than indicated, the filter should be supplied with a pump. If pressure in the water supply system is higher than indicated, it is necessary to install a pressure regulator at the inlet before the reverse osmosis filter. ** If pressure is lower or higher than indicated, it is necessary to pump up or release the pressure. *** If the temperature of feed water is within the range +20…+30 °C, selectiveness of the membrane insignificantly decreases, and capacity increases leading to insignificant growth of the TDS indicator. Application of the filter when the temperature of feed water exceeds +30 °C is not recommended. R.O. MEMBRANEReverse osmosis (RO) is a water purification technology that uses a semipermeable membrane to remove particles and ions from drinking water. This membrane technology is not considered a proper filtration method. In reverse osmosis, an applied pressure is used to overcome osmotic pressure, a colligative property that is driven by chemical potential, a thermodynamic parameter. Reverse osmosis technique is widely applied in both industrial and residential aspects to remove molecules, ions, bacterial, virus and other toxicant. Ordinary water filters use a screen to separate only particles of dirt sediments from water. Reverse osmosis employs a semipermeable membrane that removes not only particles but also an extremely high percentage of dissolved contaminants-molecule by molecule- from raw tap water. The membrane consists of several thin layers or sheets of film that are bonded together and rolled in a spiral configuration around a plastic tub (This is also known as a thin film composite or TFC membrane.) The material of the membrane is semi-permeable : it allows water molecules pass through while acting as a barrier to dissolved solids (for example, mineral, chemical contaminants, heavy metal ions) When the feed water stream passes across the surface of the membrane, the molecules penetrate the membrane surface, working their way around the spiral and collecting in the center tube. The remaining contaminants are “concentrated” and washed from the surface of the membrane down the drain (waste water). The pure water or known as “permeate” will be collected in the center tube and become the product water of RO systems. | |||||||||||||||||

| OEM Item | 70 | ||||||||||||||||